Navigate Challenging Terrain: Why Picking the Right Undercarriage Parts Issues

Navigate Challenging Terrain: Why Picking the Right Undercarriage Parts Issues

Blog Article

Take Full Advantage Of Performance With Long Lasting Undercarriage Components

In the world of heavy equipment and devices, the function of undercarriage components is vital in guaranteeing optimum performance and durability. The efficiency and efficiency of these components can dramatically influence the total operation of equipment, making the selection of long lasting undercarriage parts an essential choice for operators and supervisors alike. By discovering the detailed relationship in between sturdiness and efficiency in undercarriage parts, a deeper understanding of the subject arises, dropping light on the pivotal aspects that drive functional success. As we navigate with the intricacies of undercarriage part, longevity, and upkeep selection, a thorough exploration awaits to reveal the crucial strategies for accomplishing peak performance in durable applications.

Benefits of Utilizing Long Lasting Undercarriage Components

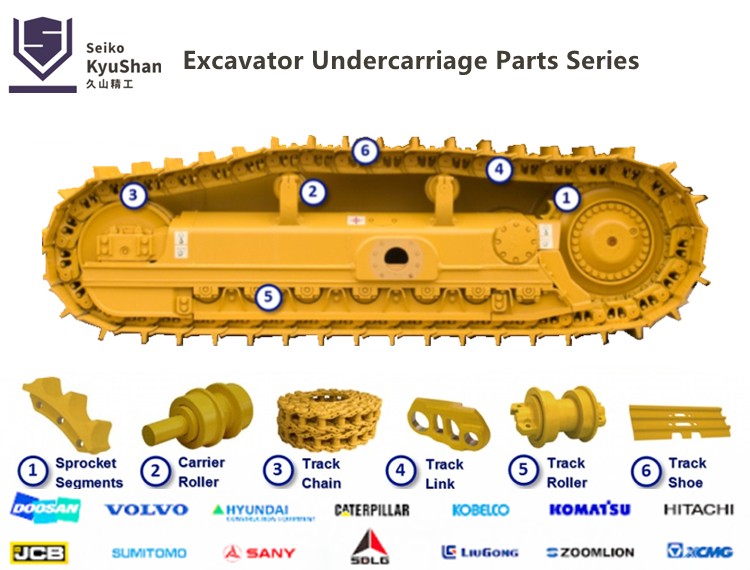

Utilizing resilient undercarriage parts not just improves the durability of heavy machinery but also reduces maintenance costs considerably. By investing in top notch undercarriage elements, such as tracks, idlers, gears, and rollers, equipment drivers can experience increased uptime and improved overall efficiency.

In addition, the longevity of heavy equipment is straight connected to the quality of its undercarriage parts. Long lasting parts can withstand the rigors of demanding applications, making sure that the equipment stays functional for extensive durations. Because of this, operators can avoid expensive downtime and maintenance expenses, ultimately optimizing the roi for their machinery.

Variables Affecting Undercarriage Longevity

The resilience of undercarriage parts in heavy machinery is influenced by different important factors that directly impact efficiency and durability. One of the key aspects impacting undercarriage toughness is the top quality of products utilized in manufacturing. Top notch products, such as hard steel, are crucial for withstanding the severe problems and heavy loads that undercarriage parts undergo. Correct maintenance practices also play a crucial duty in establishing the life-span of undercarriage components. Normal assessments, lubrication, and timely replacement of damaged parts can considerably extend the durability of the undercarriage.

Additionally, environmental factors can have a significant effect on the long life of undercarriage parts. Exposure to unpleasant materials, severe temperatures, and rough working conditions can accelerate deterioration on undercarriage components. Choosing undercarriage components that are specifically created to hold up against these environmental difficulties is essential for guaranteeing longevity.

In addition, the design and engineering of undercarriage parts have a straight impact on their longevity. Parts that are developed to distribute tons uniformly, reduce friction, and reduce anxiety focus are more probable to have a much longer life-span - undercarriage parts. By taking into consideration these crucial elements, devices operators can make best use of the durability and performance of their undercarriage parts

Upkeep Tips for Lengthening Undercarriage Life

Carrying out regular upkeep routines is important for expanding the life expectancy of undercarriage components in hefty equipment. Furthermore, guarantee that the undercarriage is properly lubed according to producer standards to decrease rubbing and stop premature wear.

Another crucial maintenance pointer is to keep the undercarriage tidy from dirt, rocks, and particles. Buildup in the undercarriage can speed up wear and corrosion, causing costly repair services. Cleaning the undercarriage after operation in rough conditions is advised to stop these problems.

Finally, monitoring and recording upkeep tasks can help in developing an aggressive maintenance routine. Keeping comprehensive records of repair services, replacements, and evaluations can provide important insights into the undercarriage's condition and efficiency in time, aiding in forecasting and avoiding prospective failures. By complying with these upkeep ideas diligently, operators can considerably increase the resilience and performance of undercarriage parts in heavy machinery.

Selecting the Right Undercarriage Elements

Picking suitable undercarriage components is important for making best use of the performance and long life of hefty equipment. When it comes to choosing the best undercarriage parts, there are numerous aspects to take into consideration. One key aspect is comprehending the particular needs of the maker and the atmosphere in which it will run. Various applications may ask for different types of undercarriage components, such as tracks, sprockets, idlers, and rollers. It is vital to select parts that are made to hold up look at more info against the particular problems the maker will certainly run into, whether it be harsh terrain, rough materials, or extreme temperature levels.

In addition, thinking about the high quality and track record of the supplier is essential. Going with credible brands recognized for creating high-performance and long lasting undercarriage parts can dramatically impact the overall performance and durability of the equipment. Additionally, ensuring that the components are compatible with the machine version and effectively set up is essential for optimum efficiency. By thoroughly choosing the best undercarriage elements, equipment proprietors can improve productivity, decrease downtime, and expand the life expectancy of their heavy equipment.

Study: Boosted Performance With Long Lasting Components

Incorporating long lasting undercarriage parts has demonstrated considerable improvements in machinery performance. One case research study involved a construction company that updated its excavator's undercarriage components to more sturdy options. The business observed a remarkable decrease in downtime as a result of undercarriage upkeep, leading to increased productivity and cost financial savings. The sturdy parts endured rough working conditions, lowering deterioration dramatically.

In an additional instance, a mining procedure changed the undercarriage components of its bulldozer with premium, sturdy choices. This switch resulted in an amazing improvement in the bulldozer's maneuverability and general efficiency. The equipment might browse tough terrains a lot more efficiently, bring about enhanced operational efficiency and minimized gas intake.

In addition, a logging firm invested in resilient undercarriage components for its forestry equipment. These situation researches underscore the concrete benefits of making use of long lasting undercarriage parts in optimizing equipment performance and longevity.

Final Thought

To conclude, utilizing long lasting undercarriage parts can dramatically boost performance and longevity of heavy equipment. Variables such as correct maintenance and selecting the here are the findings ideal elements play a crucial function in making best use of undercarriage resilience. By executing these approaches, companies can minimize downtime, boost performance, and ultimately save money on functional costs. Situation studies have shown that buying resilient undercarriage parts can bring about enhanced general efficiency and efficiency in different markets.

The efficiency and performance of these parts can considerably influence the total operation of machinery, making the selection of durable undercarriage components a crucial decision for supervisors and operators alike.Incorporating resilient undercarriage parts has actually demonstrated considerable enhancements in machinery efficiency. These case researches underscore the concrete benefits of why not try this out utilizing durable undercarriage components in optimizing equipment efficiency and durability.

In conclusion, making use of sturdy undercarriage components can dramatically enhance performance and durability of heavy equipment (undercarriage parts). Instance studies have revealed that spending in long lasting undercarriage parts can lead to enhanced total efficiency and performance in various markets

Report this page